Consistency!

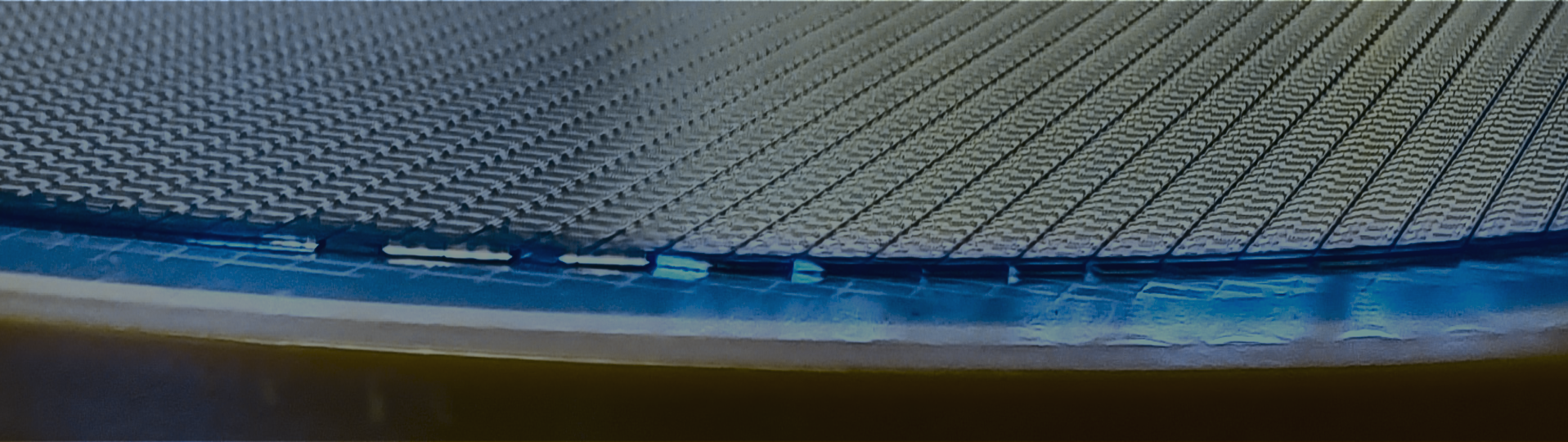

Wafers – Diced Wafers

Waffle – Gel Packs and Modules

Benefit from consistency on your production floor and reduce reliance on interpretation.

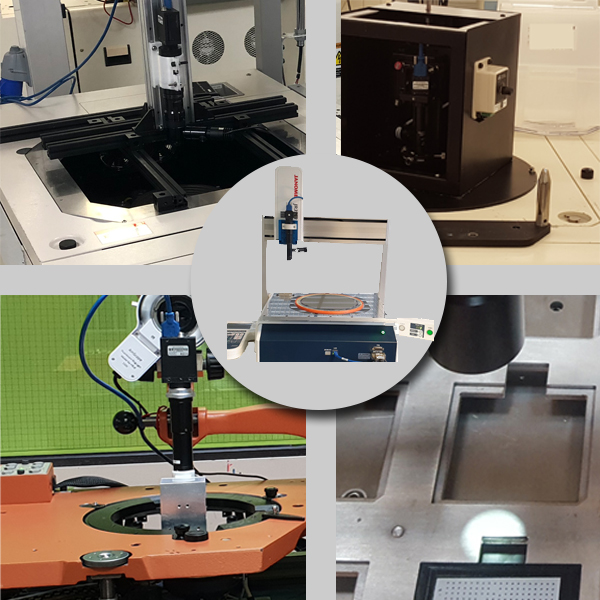

The Scrutiny Systems framework is the most flexible available.

Whatever you need to inspect (small or large) – just give us a call

Fast ROI

By focussing just on essential capability, we keep cost to a minimum.

Automated

Fitting easily into your production line, you now have the tools for productivity.

Consistent

Don’t rely on operator interpretation. Get real results for your production and quality needs.

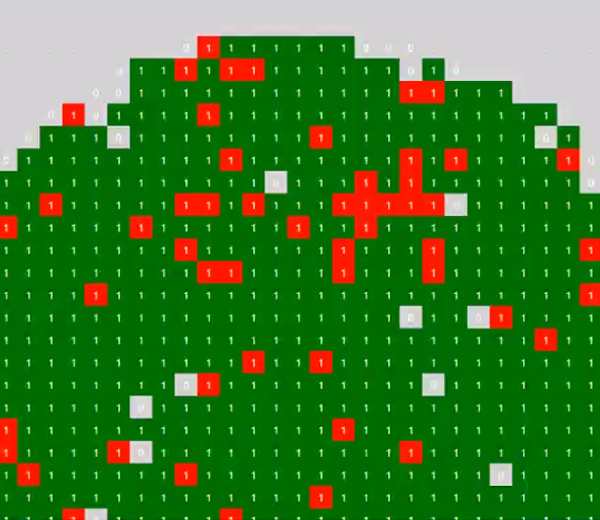

Input-Output data in a friendly, meaningful way

Data handling is key to a successful strategy. We provide the tools for networking, importing and exporting data. Standard electrical test data-maps can be loaded with bin information etc.

Enhance your AOI production strategy

By adding a consistent filter to pass-fail-review criteria your productivity is improved. Review tools ensure efficient monitoring – even remotely.

Typical Defects

Dirt – Debris – Scratches – Probe mark, Ball analysis – Process defects – Plus many more…..

Instantly see trends of potential misprocessing

Stand-alone, Robot or Prober top

Incoming & Outgoing Quality Assurance

“Point of Interest” sub-routines automate and record repetitive tasks to ensure your incoming or out going products meet specifications and requirements.

Spot Checks and archive for quality monitoring

However your tests are specified, results will be consistent

Multi-lens options can make manual microscope inspection obsolete.

Review or re-process results from anywhere

Our network and remote architecture means you don’t have to be in front of a machine to review or reprocess results – you can be in the comfort of your desk or even working from home.

Customer Comment

“The ability to pass/fail and review modes production fails from anywhere brings new capability to our QA control”

Customer Comment

“Using the systems as a production filter, means manually review less product, speeding everything up in production”

Customer Comment

“Operators are happier, as their time is now spent on analysis rather than spotting and counting defects”

Let’s work together to improve your quality,

traceability, and increase your profits!

In a data driven world, our toolkit identifies problems early, reducing customer returns or costly product recalls.